الكولاجين من النوع الأول هو بروتين حيوي وموجود بشكل واسع في جسم الإنسان؛ هذا البروتين الفريد هو ما يساعد على الحفاظ على قوة وصحة العظام والجلد والأوتار، تمامًا كما تفعل شركة ياوهاي. تصنيع بروتين Parkin рекомбинانت . شركة المنتجات الطبية ياوهاي تعمل على اكتشاف طرق بديلة أو محسنة لإنتاج الكولاجين من النوع الأول. في هذه المقالة، سنناقش بعض الأفكار حول ذلك وكيفية تخيلهم لعملية إنتاج الكولاجين من النوع الأول بطريقة جديدة.

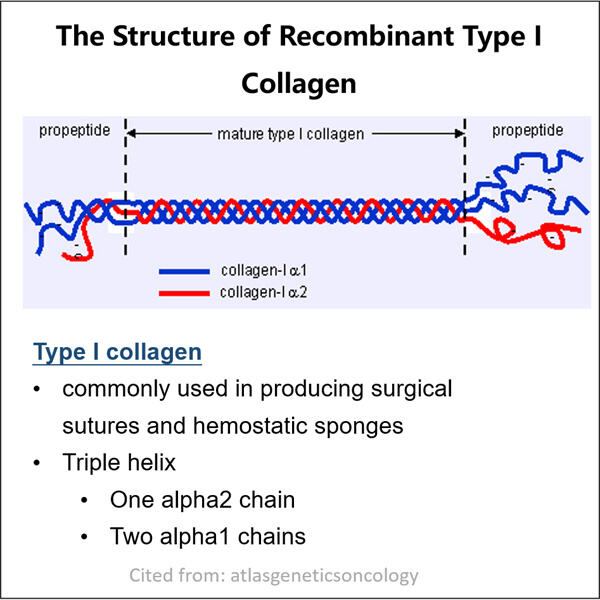

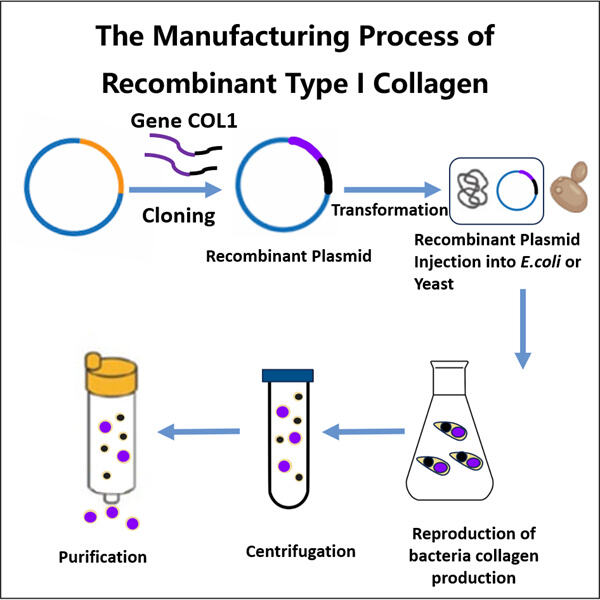

إحدى الطرق هي باستخدام التكنولوجيا المُعادة التشكيل. بروتين الكولاجين من النوع الأول الذي تمكن العلماء من إنتاجه باستخدام طريقة البكتيريا الفريدة. يتم برمجة البكتيريا بواسطة الحمض النووي، الذي يخبرها بكيفية إنتاج البروتين. ثم تتبع البكتيريا هذه التعليمات وتنتج البروتين في نظام مغلق بالكامل بحيث يمكنها فقط التركيب في ظروف مضبوطة للغاية وأمنة. هذه الطريقة أسرع وأسهل من الحصول عليه من الحيوانات.

بالإضافة إلى ذلك، تعمل ياوهاي على تطوير طرق جديدة لإنتاج الكولاجين من النوع الأول باستخدام طرق مبتكرة، وكذلك تصنيع VLP لفيروس بكتيري AP205 تُزوِّد ياوهاي. ولحسن الحظ، فإن الطباعة ثلاثية الأبعاد هي واحدة من هذه الطرق الرائعة. يتم استخدام الطابعات الخاصة لوضع طبقات المواد فوق بعضها البعض وتشكيل منتج ثلاثي الأبعاد في عملية الطباعة ثلاثية الأبعاد. يقوم الباحثون في ياوهاي بتطبيق هذه التقنية الرائعة لنمو الهياكل التي تشبه أنسجة الإنسان. ثم يضيفون بروتين الكولاجين من النوع الأول إلى هذه الهياكل. سيسمح هذا بتطوير نماذج أكثر قوة وواقعية لأنسجة الإنسان التي يمكن دمجها في المنتجات الطبية.

وجدت ياوهاي أيضًا طريقة مثيرة لإنتاج الكولاجين من النوع الأول باستخدام النباتات وليس الحيوانات. إنهم يبحثون عن مصادر أخرى للبروتين بخلاف المستمدة من الحيوانات، مثل فول الصويا أو الذرة لاستخراج البروتين. لن يكون هذا فقط أكثر صداقة للبيئة، ولكنه سيكون أيضًا أرخص. ومع ذلك، يمكنهم القيام بذلك بطريقة أكثر لطفًا تجاه كوكبنا وإنتاج الكولاجين من النوع الأول من مصادر نباتية.

اكتشفت ياوهاي طريقة جديدة لإنتاج الكولاجين من النوع الأول من خلال طرق التصنيع التي تكون مفيدة للكثير من القضايا، إلى جانب منتج ياوهاي تصنيع المستضدات السرطانية المُعاد تشكيلها . ولكن من خلال إعادة التركيب الجيني، يمكنهم هندسة البكتيريا لإنشاء البروتين بطريقة أسهل وأكثر كفاءة. مما له ميزة في الممارسة أنهم ينتجون كميات ضخمة من البروتين بسرعة، لذلك يكون إنتاجه أرخص وأكثر اقتصادية للاستخدام الطبي الفموي.

يقلل الكولاجين من النوع الأول TI من أنواع الأشياء التي تسبب ألمًا في العظام والجلد والأوتار مع تقدمنا في العمر، عملية جديدة مهمة للكثير منا الذين نحتاج إلى إنتاج علاجات أفضل تساعدنا على الوقوف دون ألم. وكذلك تفكيك وإعادة تجميع VLP تصنع بواسطة Yaohai. مع زيادة عدد السكان المسنين، يزداد الطلب على هذه الأنواع من المنتجات الطبية. تحتوي كل من هذه المنتجات على الكولاجين من النوع الأول كجزء من مكوناتها، لذلك فإن الطلب على أحدها يعني زيادة الطلب على الآخر. يساهم العمل الابتكاري لمصنع Yaohai في تعزيز هذه القدرة.

لعبت الكفاءة المحسنة داخل Yaohai دورًا في جعل البروتين أرخص وأعلى جودة، بالإضافة إلى منتج Yaohai تصنيع مشتق GLP-1 . لقد صنعوا بروتين الكولاجين من النوع الأول أكثر نقاءً واتساقًا باستخدام التكنولوجيا الإعادة التركيبية. وهذا يعني أن بعض المنتجات الطبية المصنوعة باستخدام هذا البروتين ستكون أفضل، وهو أمر جيد للمرضى ومقدمي الرعاية الصحية على حد سواء.

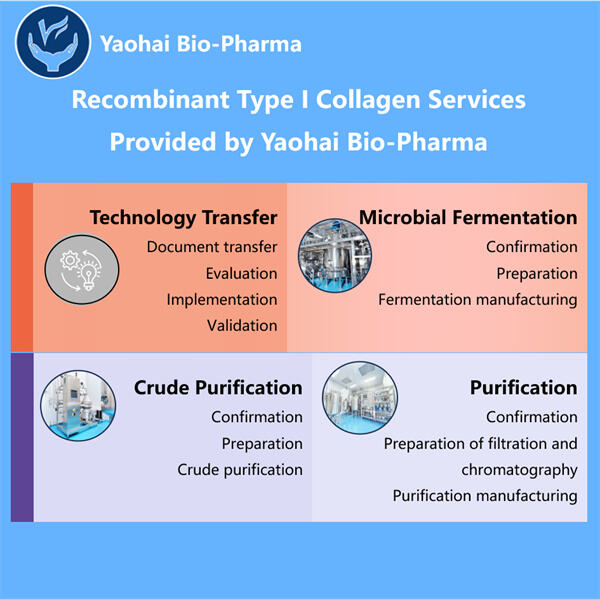

ياوهاي بيو-فارما، واحدة من أكبر 10 منتجين للكولاجين من النوع الأول المُعاد تشكيله، تخصصت في التخمير المجهرى. لقد أنشأنا منشأة حديثة تحتوى على مرافق متقدمة وقدرات تصنيعية قوية في البحث والتطوير. هناك خمس خطوط إنتاج مواد دوائية تتوافق مع معايير GMP للتنقية الميكروبية والتخمير، بالإضافة إلى خطين آليين لإكمال عملية الملء للأمبولات والكراطيش والإبر المسبقة الملء. تتراوح أحجام التخمير بين 100 لتر و2000 لتر. مواصفات ملء الأنبوب الزجاجي تغطي من 1 مل إلى 25 مل، بينما تكون مواصفات ملء الكراطيش أو الإبر المسبقة الملء بين 1-3 مل. ورشة الإنتاج معتمدة حسب معايير cGMP وتقدم عينات تجارية وسريرية. مصنعنا ينتج الجزيئات الكبيرة التي يتم تصديرها إلى جميع أنحاء العالم.

ياوهاي بيو-فارما هي شركة رائدة في مجال خدمات التطوير والتصنيع المتعاقدة للمنتجات الحيوية الدقيقة. كان تركيزنا الأساسي على إنتاج الكولاجين من النوع الأول рекомبنانت وعلاجات لرعاية الحيوانات الأليفة، الصحة البشرية والبيطرية. لدينا منصات بحث وتطوير متقدمة وتقنيات تصنيع تغطي العملية الإنتاجية بأكملها، بدءًا من تطوير سلالات دقيقة، بنوك الخلايا، تطوير العمليات والطرق، وحتى التصنيع السريري والتجاري مما يضمن تسليم حلول مبتكرة بنجاح. مع مرور الوقت، اكتسبنا معرفة واسعة في معالجة البيولوجيا القائمة على المجهريات. نفذنا بنجاح أكثر من 200 مشروع عالمي، ونساعد عملاءنا في التعامل مع القوانين واللوائح الخاصة بالهيئة الأمريكية للأدوية والأغذية (FDA)، وكالة الأدوية الأوروبية (EMA)، وهيئة تنظيم الأدوية الأسترالية (TGA)، وهيئة إدارة المنتجات الطبية الوطنية الصينية (NMPA). بسبب خبرتنا ومهارتنا، يمكننا الاستجابة بسرعة لمتطلبات السوق وتقديم خدمات CDMO مخصصة.

إنتاج الكولاجين من النوع الأول المُعاد تشكيله هو واحد من أفضل 10 شركات CDMO الدقيقة التي تدمج التحكم في الجودة والقضايا التنظيمية. لقد أنشأنا نظام جودة قوي يتوافق مع معايير GMP الحالية واللوائح في جميع أنحاء العالم. فريقنا التنظيمي على دراية واسعة بالإطارات التنظيمية العالمية لتسريع إطلاق المنتجات البيولوجية. نضمن عمليات إنتاج قابلة للتتبع ومنتجات ذات جودة عالية تتوافق مع لوائح US FDA، EU EMA، Australia TGA، و China NMPA. تمكنت Yaohai BioPharma بنجاح من اجتياز التدقيق الميداني الذي أجراه شخص مؤهل معتمد من الاتحاد الأوروبي (QP) لمراجعة نظام GMP الخاص بنا ومرافق الإنتاج. بالإضافة إلى ذلك، قد مررنا بنجاح أول تدقيقات الشهادات لنظام إدارة الجودة ISO9001، نظام إدارة البيئة ISO14001، ونظام إدارة الصحة والسلامة المهنية ISO45001.

لدى Yaohai Bio-Pharma خبرة في تصنيع الأدوية البيولوجية المصنوعة من المجهريات. نقدم حلولًا مخصصة للبحث والتطوير وكذلك خدمات التصنيع مع تقليل المخاطر إلى الحد الأدنى. عملنا مع أنماط متنوعة مثل اللقاحات الفرعية рекombinat، الببتيدات، الهرمونات، السيتوكينات، عوامل النمو، الأجسام المضادة أحادية المجال، الإنزيمات، الحمض النووي البلازميدي، الرنا المرسال وغيرها. تخصصنا في عدة مجهريات مثلخميرة الإفراز الخلوي الخارجي والداخلي (مع إنتاج يصل إلى 15 جم/لتر)، البكتيريا القابلة للذوبان داخل الخلية والأجسام الشاملة (مع إنتاج يصل إلى 10 جم/لتر). كما قمنا بإنشاء نظام تخمير BSL-2 لإنتاج الكولاجين النوع الأول рекombinat وتصنيع اللقاحات. نحن خبراء في تحسين عمليات الإنتاج، زيادة الإنتاجية وتقليل التكاليف. لدينا فريق تقني كفؤ يضمن تسليم المشاريع في الوقت المحدد وبجودة عالية. هذا يسمح لنا بتقديم منتجاتك الفريدة إلى السوق بشكل أسرع.