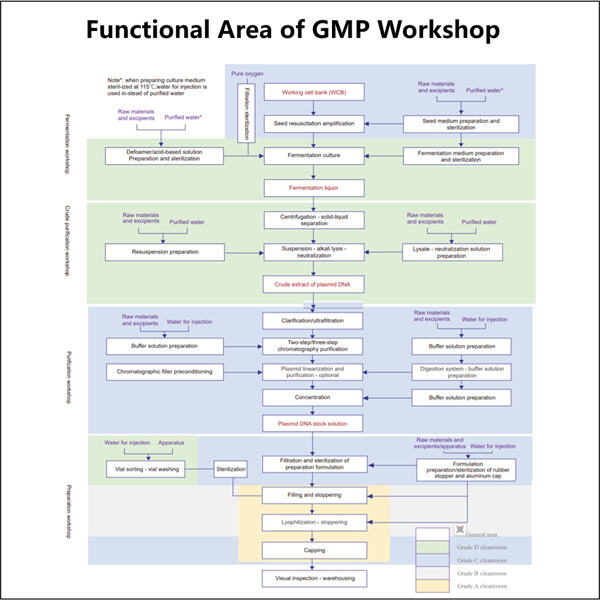

Setiap hari di Yaohai API Tirzepatide GLP-1GIP GMP , kami bekerja sangat keras untuk mengembangkan produk mikroba berkualitas tinggi. Tidak hanya terbatas pada hal tersebut, namun kami ingin agar produk-produk ini menjadi yang terbaik dalam setiap penggunaannya. Memastikan bahwa produk kami murni adalah salah satu hal paling berharga yang kami lakukan dalam pekerjaan kami. Ini berarti setelah selesai mencampurnya, tidak boleh ada kontaminan atau bahan kimia berbahaya yang tercampur. Pelanggan harus dapat mengandalkan apa yang kami sediakan dan percaya bahwa mereka mendapatkan produk dalam bentuk paling murni.

Dan untuk menjaga produk kami tetap murni, kami telah menggunakan berbagai macam metode dan teknik. Ini hanyalah jenis metode atau alat yang dapat membantu kami membersihkan hal-hal buruk yang seharusnya tidak ada di sana. Artinya, kami bisa menyaring dengan menggunakan metode seperti filtrasi yang pada dasarnya menggunakan penyaring di mana Anda menangkap semua partikel buruk dan hanya membiarkan yang baik melewati, kan? Kami juga melakukan banyak pengujian di seluruh lini produk saat produk bergerak melalui berbagai tahap produksi. Kami melakukan uji coba ini untuk memastikan semuanya bersih dan aman sebelum mencapai pelanggan kami.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN