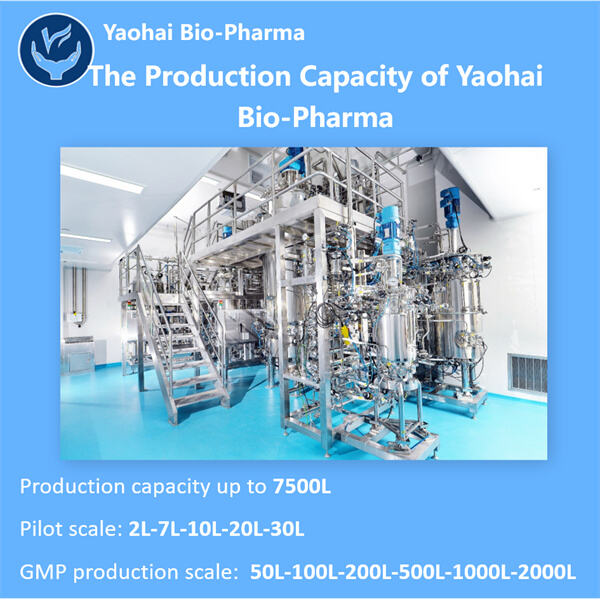

Oleh karena itu, di Yaohai, kami memahami kebutuhan GMP dalam Produksi Protein G RSV bagi kami. Ini memungkinkan kami untuk memverifikasi bahwa produk-produk kami aman dan berkualitas tinggi. Apa arti GMP untuk Produksi Protein G RSV? Kami akan membahas bagaimana kami mendefinisikan GMP atau praktik manufaktur yang baik, serta strategi-strategi berbeda yang kami gunakan untuk mencapai kualitas terbaik dari produk kami di bagian selanjutnya.

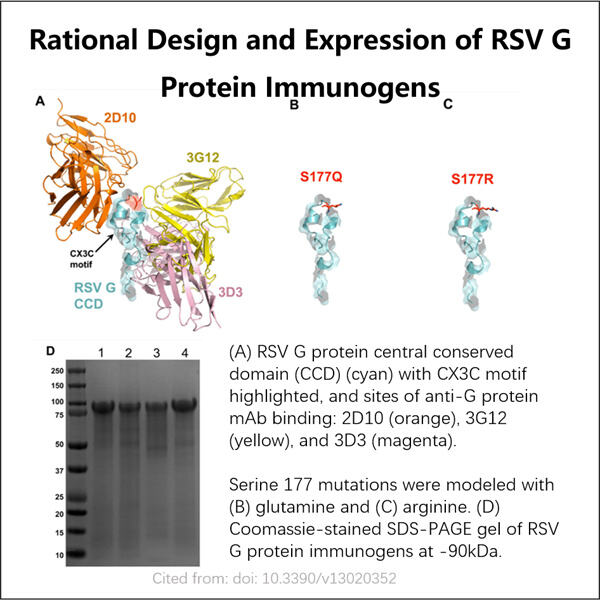

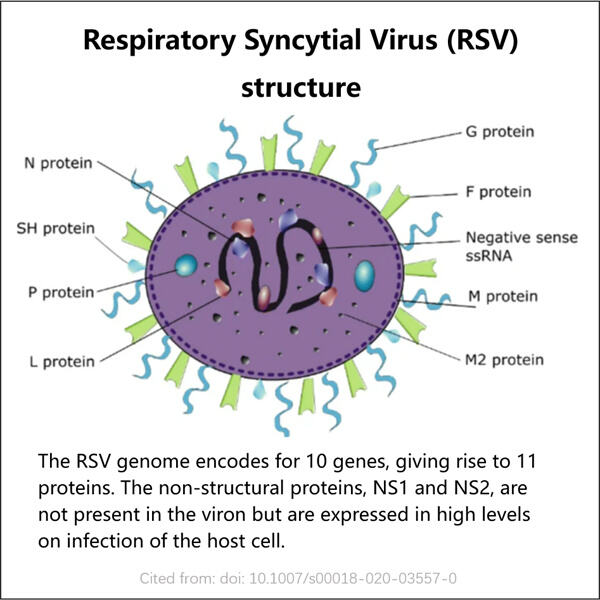

Negara-negara Berbeda Memiliki Standar yang Berbeda-Beda Sebagai Contoh: *GMP: Good Manufacturing Practice. Ini adalah panduan yang kami gunakan untuk memproduksi Protein G RSV yang aman dan efektif. Salah satu produk yang sangat penting adalah Protein G RSV yang memberikan bantuan kepada orang-orang yang sakit akibat virus yang disebut virus sinkitial pernapasan atau RSV. The Pembuatan Plasmid AAV ancaman bisa sangat parah bagi bayi, anak kecil, dan orang tua. Oleh karena itu, sangatlah penting bahwa Protein G RSV yang kami kirimkan aman dan sesuai untuk digunakan.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN