Die Reinigung der Kraft von Poly-AT Plasmiden für optimale Ergebnisse

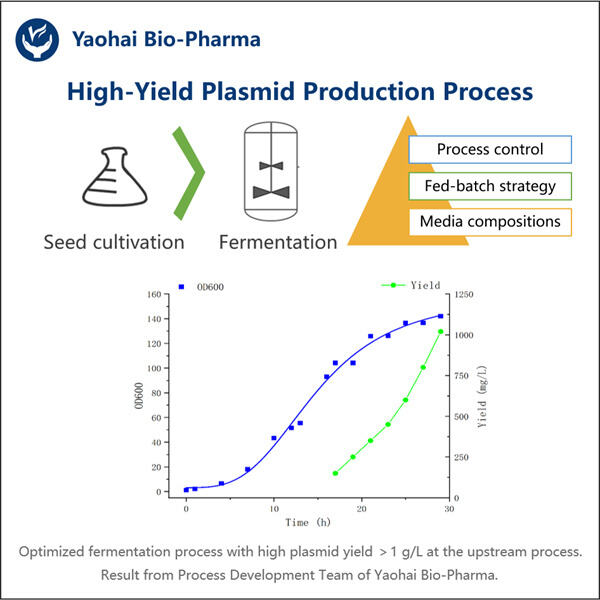

Die Fermentation ist entscheidend für hohe Erträge an Poly-AT-Plasmiden. Die von uns bei Yaohai verwendeten Bakterien sind E. coli, wo wir das Wachstum unserer Plasmide erheblich erleichtern. Dieses Typs von Bakterien wird bevorzugt, da es schnell wächst und darin begründet, dass in kurzer Zeit eine große Anzahl an Plasmiden produziert werden kann.

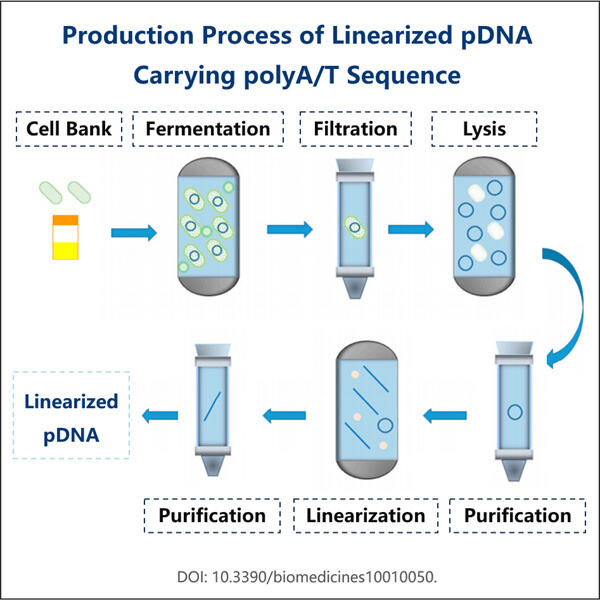

Wir wählen spezifische Temperaturen, Nährstoffe und Bedingungen aus, um das Bakterienwachstum zu ermöglichen und Massenplasmide herzustellen. Zum Beispiel könnten wir die Bakterien bei warmer Temperatur mit viel Nahrung halten, damit sie schnell wachsen. Nachdem sich die Bakterien vermehrt haben, müssen wir sie ordentlich öffnen, damit die Plasmide freigesetzt werden können. Hier kommt es wirklich, wirklich gut.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN