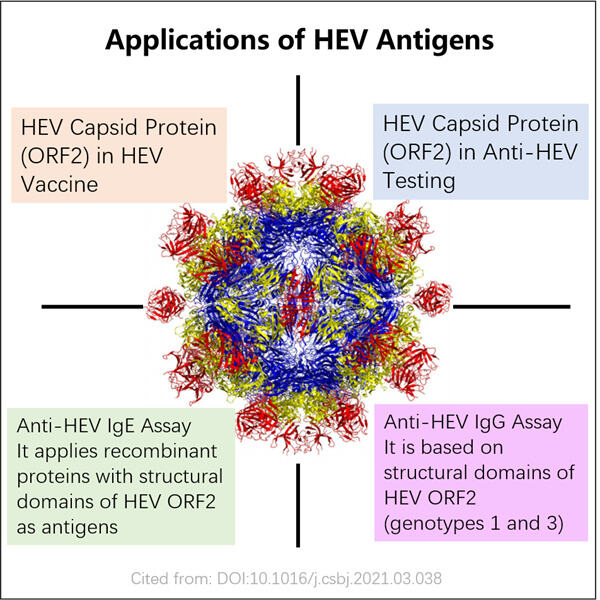

Yaohai ist ein globaler Marktführer im Bereich der HEV-Antigene, die in Diagnosen verwendet werden. Es hat uns eine immense Menge an Zeit gekostet, um einen schnellen und zuverlässigen Weg zu entwickeln, HEVs herzustellen, die in diesen Tests verwendet werden, was Jahre harter Arbeit erfordert hat. Dies kann manchmal wie viel Arbeit erscheinen, aber es stellt sicher, dass jeder Batch, den wir herstellen, konsistent ist, was wiederum ermöglicht, dass wir für unsere Kunden reproduzierbar und vorhersagbar bleiben.

Die richtigen Zellen auswählen — Der Schlüssel zur effektiven zellbasierten Herstellung von GMP CMV Antigen Herstellung . Diese Zellen sind die sehr kleinen Bausteine, die uns helfen, die Antigene herzustellen, die wir benötigen. Wir testen Zellen gegen verschiedene Zelltypen mit dem einzigen Ziel, den Zelltyp zu identifizieren, der starke Antigen-Signale von HEV aufweist. Anschließend optimieren wir die besten Zellen. Das bedeutet, sicherzustellen, dass sie eine angemessene Menge an Nahrung, Sauerstoff und Temperatur erhalten. Wir unterstützen dies, indem wir optimale Bedingungen für die Zellen schaffen, um so viele HEV-Antigene wie möglich zu generieren.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN