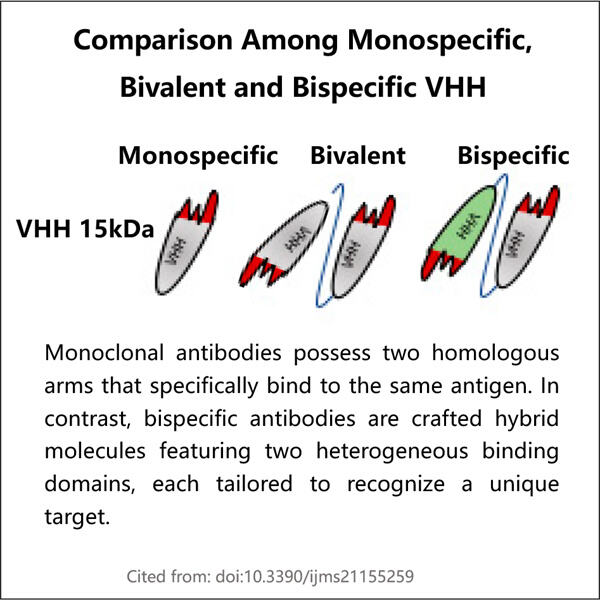

Yaohai ist ein Produktlieferant, der essenzielle Nährstoffe für das menschliche Leben bereitstellt. Ein ungewöhnliches Medikament, das sie herstellen, sind bi-spezifische VHHs. Was sind also bi-spezifische VHH? Diese bestehen aus kleinen Teilen der Anatomie, die Antikörper genannt werden. Antikörper sind die kleinen Soldaten, die unser Immunsystem einsetzt, um Krankheiten anzugreifen und uns gesund zu erhalten. Bi-spezifische VHHs sind bemerkenswert, da sie zwei separate Entitäten gleichzeitig binden können. Sie sind sehr nützlich bei der Behandlung bestimmter Krankheiten wie einiger Krebstypen.

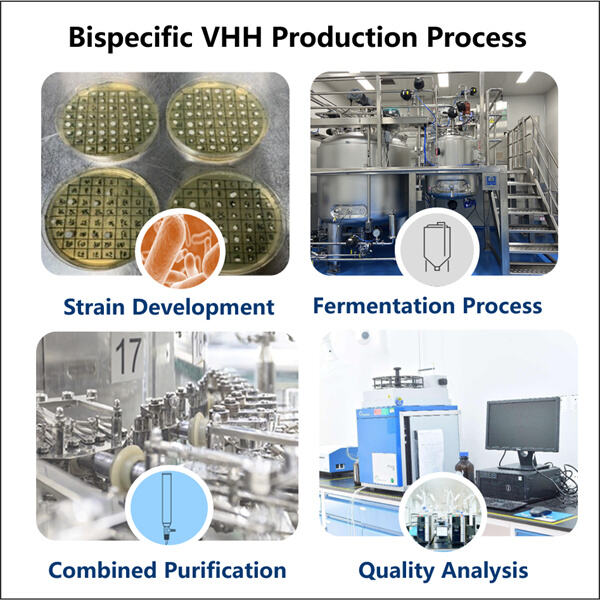

Diese bi-spezifischen VHHs werden von Yaohai unter Verwendung einzigartiger Zellen hergestellt, die als 'Expression Hosts' bekannt sind, ähnlich wie beim Yaohai-Produkt wie Herstellung von rekombinantem Insulin . Diese Ausdrucksträger, die ausgebildet werden, um genau die gleichen Antikörper herzustellen, die Yaohai für ihre Medikamente benötigt. Bisspezifische VHHs sind jedoch in der Praxis schwierig herzustellen. Manchmal produzieren die Zellen Antikörper, die NICHT richtig gebildet sind oder eine weniger wirksame Reaktion zeigen. Deshalb arbeitet Yaohai Tag und Nacht daran, sicherere und effizientere Methoden zur Herstellung von bisspezifischen VHHs zu finden.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN