هل تعرف حتى ما هو المقصود بـ mRNA؟ mRNA هو نوع من الرسائل الجينية التي تساعد الجسم على إنتاج البروتينات داخل خلايانا. تقوم البروتينات بأدوار مهمة مثل بناء العضلات الجديدة ومكافحة الأمراض. أولاً، قبل استخدام mRNA لإنتاج الأدوية، يجب تنقيتها. يشير ذلك إلى التخلص من المواد غير المرغوب فيها ويعني أن mRNA المهم فقط هو الذي يبقى. هذه المقالة تقدم بعض الأفكار حول كيفية قيام العلماء بتنقية mRNA. سنتحدث عن كيفية استعدادهم لهذه المهمة، وما هي أفضل الممارسات التي يتبعونها ويتركونها، والأهم هو مع أي أدوات جديدة ينتهون بها أثناء الطباعة مع التأكد من أن النتيجة تعمل بشكل جيد مع حالاتها الخاصة.

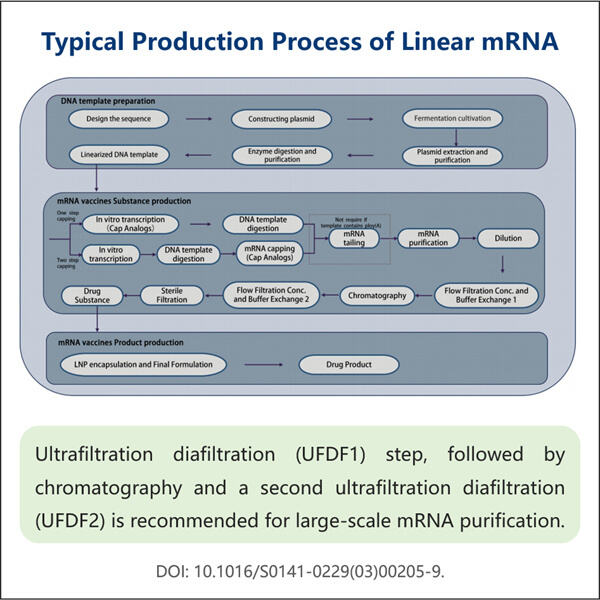

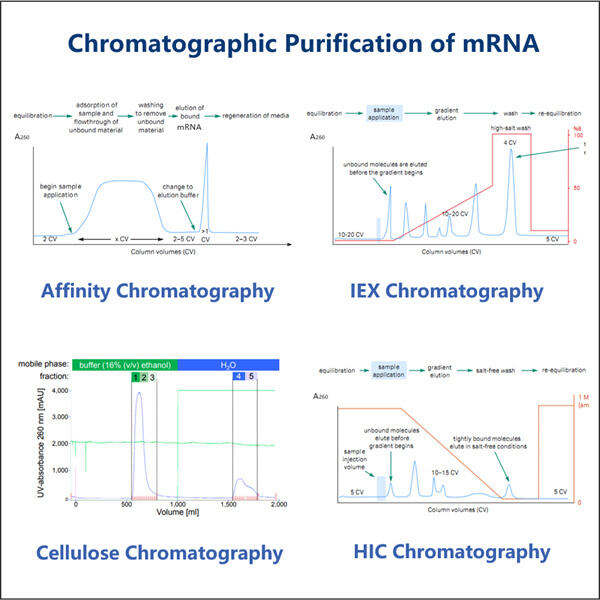

تطوير عملية يعني تعريف بروتوكول التنظيف الأمثل لـ mRNA، المطابق لمنتج Yaohai تطوير عملية تنقية البيولوجيك هذا مهم للغاية للعلماء، لأن عليهم اختيار الطرق والأدوات المناسبة لهذه المهمة.这不是总是 بديهية، وغالباً ما سيضطر العلماء إلى اختبار طرق مختلفة لتحديد ما هو أكثر فعالية. عند إنتاج الصيغة، يبحثون في بعض النقاط الحيوية. تشمل هذه الخلايا والأنسجة (جودة المادة الأساسية). كما سيحتاجون إلى تحديد كمية mRNA التي يحتاجونها لأغراضهم، سواء كان mRNA بحاجة إلى أن يكون نقيًا وما هو الهدف النهائي المقصود منه. جزء من هذا العملية يتضمن اختيار طريقة التنظيف المناسبة. يمكن أن تشمل هذه الطرق مثل الحبات المغناطيسية، الكروماتوغرافيا أو أي نوع آخر من الترشيح. لكل من هذه الطرق مزايا وعيوب استخدامها. وهذا يعتمد على أي طريقة هي الأكثر كفاءة، وأكثر موثوقية، وأكثر كفاءة من حيث التكلفة لكل حالة استخدام يحاول العلماء الإجابة عليها.

تنظيف mRNA هو عملية معقدة تتطلب ممارسات واستراتيجيات جيدة لكي تكون ناجحة، إلى جانب إنتاج مونومر VHH من ياوهاي. على مدار العملية، الشيء الحاسم هو دائمًا استخدام مواد وأدوات ذات جودة عالية. قد تكون هناك عناصر غير مرغوب فيها (الملوثات، مثل RNases أو DNA) ولهذا قد تؤثر سلبًا على mRNA وتقلل من جودته. لذلك، يجب على العلماء بذل جهود كبيرة لتجنب التلوث. يستخدمون القفازات ويستخدمون أنابيب معقمة ومناطق نظيفة للحفاظ على باقي العملية نظيفة قدر الإمكان. كما يتضمن فلسفة التطوير القوية التحقق من صحة العملية لضمان عمل الاختبارات كما هو مخطط لها. أثناء التنظيف، يمكن للعلماء أيضًا استخدام طرق ضبط الجودة - مثل التحليل الكهربائي بالجيل أو الطيفية الضوئية - لتقييم سلامة ونقاء RNA. هذه هي الفحوصات التي تساعد في التأكد من أن العمل يتم بشكل جيد وموثوق.

تحسين العمليات يعني توفير الوقت والمال أثناء عملية التنظيف، وكذلك منتجات ياوهاي مثل بنوك خلايا الخميرة . هناك العديد من الطرق التي يمكن من خلالها جعل الحمض النووي الريبي المرسال (mRNA) نقيًا. على سبيل المثال، الخطوات التي تسبق عملية التنقية الفعلية، مثل كسر الخلايا، يمكن أن يكون لها تأثير كبير على كمية mRNA النقي المنتجة في النهاية. بالنسبة لهذه الخطوات، غالبًا ما يرغب الباحثون في اكتشاف طرق وظروف جديدة تؤدي إلى الحصول على أعلى جودة من mRNA لتلبية احتياجاتهم. يمكنك أيضًا استخدام الأجهزة التي يمكن أن تمكن التحكم الآلي في العملية وتوفير الوقت في سير العمل. هذه الأنظمة قادرة على معالجة العديد من العينات في وقت واحد، مما يقلل من الأخطاء البشرية ويقدم نتائج متسقة. يجعلك التحكم الآلي قادرًا أيضًا على توسيع العملية عند الحاجة وفي أي مكان.

بالتأكيد، البحث العلمي يدور حول الطرق الجديدة والمُحسّنة لكل شيء — تنقية mRNA ليست استثناءً، وكذلك تصنيع تخمير الجراثيم صنعت بواسطة Yaohai. على مر السنين، تم تطبيق تقنيات وتطبيقات جديدة لتطوير معالجة التنقية. على سبيل المثال، قام العلماء بصنع كرات صغيرة من المعادن ومغلفة بمادة لاصقة (نانو جسيمات) لتتصرف مثل إسفنج جزيئي – حيث تلتصق، تمتص وتحتفظ بجزيئات mRNA لنفسها. يمكن استخدام النانو جسيمات بالتزامن مع الكرات المغناطيسية أو أدوات أخرى لتسريع تنقية mRNA. بالإضافة إلى ذلك، تم تطوير طرق بديلة لالتقاط وتحليل mRNA مثل التقاط المستند إلى الميكروآرري أو تسلسل RNA بعد تقليل الريبوزومات. توفر هذه التكنولوجيات والتقنيات الجديدة للعلماء مرونة أكبر في تصميم عملية تنقية mRNA الخاصة بهم، مما يمكّنهم من تحقيق أهدافهم بشكل أفضل.

يجب أن يكون المنتج النهائي، وهو mRNA المُنقى، قابلاً للتكرار والثبات من حيث الاستخدام المقصود. سيعتمد كل هذا على أساليب السيطرة على الجودة الجيدة التي وضعها العلماء، تمامًا كما هو الحال مع منتج Yaohai الذي يسمى إنتاج مادة بيولوجية مشابهة لـ PTH 1-34 . على سبيل المثال، باستخدام التحليل الكهربائي للجيل أو تحليل التسلسل للتحقق من طبيعة mRNA المُنقَّى. يمكنهم أيضًا مقارنة ذلك بمكتبتهم من العينات الأخرى للتأكد من أن mRNA نقي وغير متضرر، في حال أثرت عملية التنظيف على mRNA. يمكن تقييم استقرار mRNA ومدة صلاحيته باستخدام هذه الطرق أيضًا. وللتخزين الطويل الأمد، يمكن للعلماء تخزين mRNA عند درجات حرارة منخفضة أو تجفيفه بالتجميد. وفي النهاية، فإن استمرارية المنتج النهائي أمر حاسم لتحقيق الفعالية، سواء كان ذلك في تطبيقات معملية أو تطبيقات واقعية مثل اللقاحات أو علاج السرطان

ياوهاي بيو-فارما، وهي واحدة من أكبر 10 مصنعي المنتجات البيولوجية، متخصصة في التخمير المجهربي. لقد أنشأنا مصنعًا فعالًا يحتوي على مرافق متقدمة وقدرات قوية في البحث والتطوير والإنتاج. هناك خمس خطوط إنتاج مواد دوائية تتوافق مع معايير GMP للتخمير المجهربي والت精يف، بالإضافة إلى خطين لتعبئة الأنبوب الزجاجي والكراطيش والحقن المسبقة التعبئة. تتراوح أحجام التخمير بين 100 لتر ومفاعل mRNA للتنقية. مواصفات التعبئة للأنبوب الزجاجي هي من 1 مل إلى 25 مل. أما بالنسبة للتعبئة بالكراطيش أو الحقن المسبقة التعبئة فهي من 1-3 مل. ورشة الإنتاج متوافقة مع cGMP وتضمن توفير العينات السريرية والتجارية بشكل مستمر. منشأتنا تنتج الجزيئات الكبيرة التي يتم شحنها عالميًا.

ياوهاي بايو فارما، وهي شركة تطوير عمليات تنقية mRNA وشركة CDMO ميكروبية، تدمج شؤون التنظيم والجودة. لدينا نظام جودة متوافق مع المعايير الحالية لـ GMP، وكذلك اللوائح في جميع أنحاء العالم. فريقنا التنظيمي على دراية بالإطارات التنظيمية العالمية لتسريع إطلاق المنتجات البيولوجية. نحن نتأكد من أن العمليات الإنتاجية قابلة للتعقب، وتنتج منتجات ذات جودة عالية، وتتوافق مع قواعد FDA الأمريكية وEMA الأوروبية. كما يتم الوفاء بمتطلبات TGA الأسترالية وNMPA الصينية أيضًا. لقد نجحت ياويهاي بايو فارما في اجتياز التدقيق الميداني لشخص المؤهل (QP) في الاتحاد الأوروبي لضمان نظام الجودة الخاص بنا وموقع الإنتاج وفقًا لنظام GMP. كما اجتزنا أيضًا التدقيقات الأولية لنظام إدارة الجودة ISO9001 ونظام إدارة البيئة ISO14001.

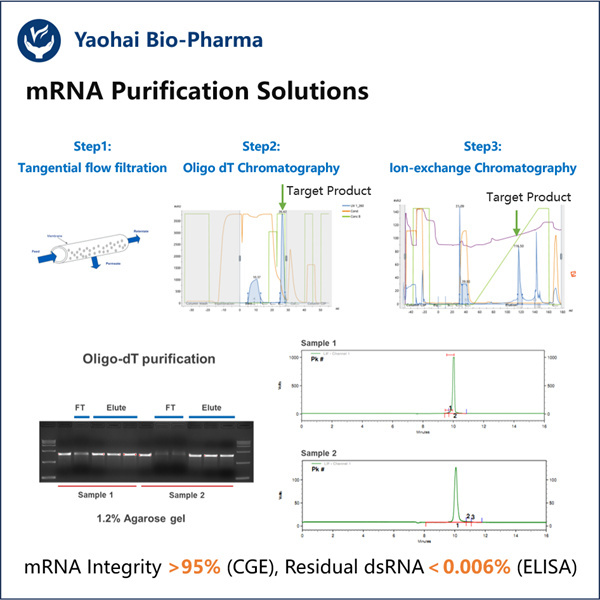

ياوهاي بيولوجي فارما هي رائدة في مجال خدمات التطوير والتصنيع المتعاقدة للميكروبات الحيوية. كان تركيزنا الأساسي على إنتاج اللقاحات العلاجية الميكروبية لإدارة صحة الحيوانات الأليفة، البشر والحيوانات. نحن نمتلك منصات تكنولوجية حديثة للبحث والتطوير والتصنيع تغطي العملية بأكملها، من هندسة سلالات الميكروبات، بنوك الخلايا، تصميم العمليات والطرق إلى التصنيع السريري والتجاري، مما يضمن توفير أحدث الحلول بنجاح. عبر السنوات اكتسبنا خبرة واسعة في استخدام المصادر الميكروبية. تم تنفيذ أكثر من 200 مشروع بنجاح. بالإضافة إلى ذلك، ندعم عملاءنا في المرور عبر اللوائح التنظيمية مثل تلك الخاصة بالهيئة الأمريكية للأدوية والأغذية (FDA) والوكالة الأوروبية للأدوية (EMA). كما نساعد العملاء في التعامل مع الهيئة الأسترالية لتقييم الأدوية (TGA) والهيئة الوطنية الصينية لإدارة المنتجات الطبية (NMPA). تمكننا معرفتنا المتخصصة وخبرتنا الواسعة من الاستجابة بسرعة لاحتياجات السوق وتوفير خدمات التطوير التعاقدية لعملية تنقية mRNA.

ياوهاي بيو-فارما هي شركة متخصصة في تطوير عملية تنقية mRNA في البيولوجيات المستخلصة من الميكروبات. نقدم حلول بحث وتطوير مخصصة وكذلك حلول تصنيع مع تقليل المخاطر. كنا متورطين في العديد من الأنواع مثل لقاحات الوحدة المركبة، والهرمونات الببتيدية، والسيتوكينات والعوامل النمو، والضدود ذات المجال الواحد، والأنزيمات، وDNA الحلزوني، والمُرَنَة RNA وغيرها. نحن خبراء في عدة مستضيفات دقيقة مثلخميرة خارج الخلية وداخلها (الإنتاج يصل إلى 15 جراماً لكل لتر)، وإفراز غشاء البكتيريا وتشمل الجزيئات القابلة للذوبان داخل الخلايا (الإنتاج يصل إلى 10 جرام/لتر). بالإضافة إلى ذلك، طورنا منصة تخمير ميكروبية المستوى BSL-2 لتطوير لقاحات البكتيريا. لدينا سجل حافل في تحسين عمليات الإنتاج، مما يؤدي إلى زيادة الإنتاج وتقليل التكاليف. ومع فريق تقني ذو كفاءة عالية، نضمن تسليم المشاريع بشكل سريع وموثوق ونجلب منتجاتكم إلى السوق بشكل أسرع.