على الرغم من أن اللقاحات تعد مكونًا أساسيًا في المعركة ضد العديد من الأمراض، إلا أن هناك بعض الأمراض (مثل السرطان) التي تحتاج إلى أكثر من مجرد تلقيح. فهي تحتاج إلى دواء فريد للعلاج. السرطان هو مرض خطير ومثير للخوف يجعل الناس يمرضون بشدة ويمكن أن يغير حياتهم بطرق عديدة. العلماء دائمًا ما يعملون على طرق بديلة ومتقدمة لمكافحة السرطان. وأكثر ما يلفت الانتباه هو الفرصة والأمل التي تمثلها Yaohai إنتاج VHH مضاد HER3 وفق معايير GMP والتي تعتقد شركة Avillion أنها تملكها بين يديها.

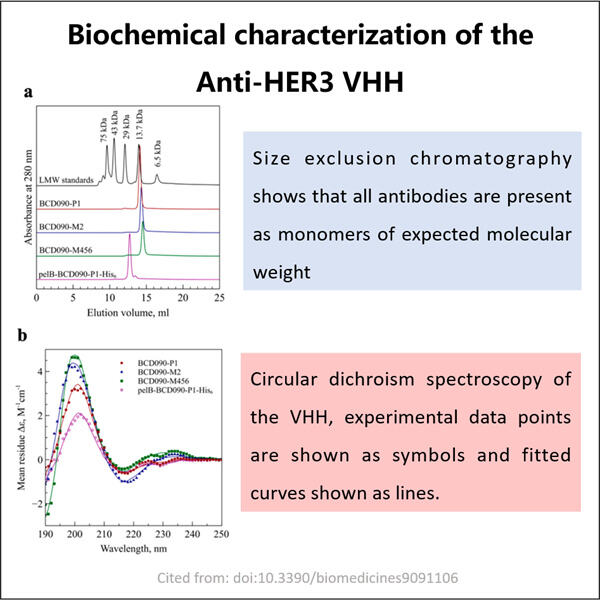

مثل العديد من خلايا السرطان الأخرى، Yaohai إنتاج VHH مضاد HER3 وفق معايير GMP هو بروتين تم تحديده في أنواع مختلفة من السرطانات. يمكّن هذا البروتين الخلايا السرطانية من النمو بشكل مفرط والتوزع في جميع أنحاء الجسم. يتم تطوير جزء من مضاد حيوي يُسمى VHH بواسطة العلماء. يمكن لهذا VHH الارتباط بالبروتين HER3 مما يمنعه من العمل. ومن هنا يُطلق عليه GMP anti-HER3 VHH. عندما يتم حجب البروتين HER3، يتم انتشار الكيميوكين CXCL12 والصفراء في الطحال لدى الحيوانات بحيث قد تنمو الخلايا السرطانية بمعدل أبطأ أو تبقى بمعدلات طبيعية أثناء العمليات التنموية.

بسبب Yaohai GMP Anti-MMRCD206 VHH يجب أن تكون آمنة للمرضى وفعّالة في علاج السرطان، يتبع العلماء لوائح صارمة للغاية. وهذه هي القواعد الأساسية واللوائح التي تُعرف باسم إرشادات الممارسات الجيدة لتصنيع الأدوية (GMP). تهدف هذه الخطوات التحكمية إلى ضمان إنتاج مركبات GMP المضادة لـ HER3 في بيئة نظيفة وآمنة. وهذا مهم جدًا، لأن وجود أي دنس أو تلوث قد يجعل الدواء غير آمن للاستخدام البشري وقد يمنع الدواء من العمل بشكل صحيح.

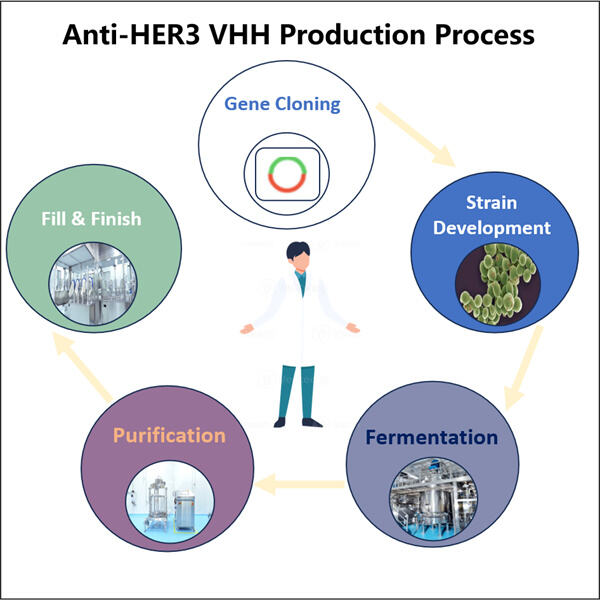

تصنيع ياوهاي GMP Anti-MMRCD206 VHH هو عملية معقدة ومتعددة المراحل. في البداية، قام العلماء بتصميم خلايا محددة لإنتاج هذه VHHs. ثم يتم نقلها إلى حاضنة بيولوجية بمجرد استعداد هذه الخلايا. ستنمو هذه الخلايا وتنتج VHHs في هذه الحاضنة البيولوجية. بعد ذلك، تمر VHHs بخطوة إضافية تسمى التصفيه. وهذا يتضمن إزالة الأجزاء الزائدة وهضم الباقي للحفاظ على VHHs فقط. وأخيرًا وليس آخرًا، يتم تعبئة VHHs بعناية في زجاجات صغيرة - نسميها أنابيب - حتى يمكن استخدامها لعلاج مرضى السرطان بشكل صحيح.

اكتشاف ياوهاي GMP GLP-1GIP Tirzepatide API هو مجرد خطوة أولى في تطوير عصر جديد من الفعالية والعلاج الأقل سمية للسرطان. دائمًا هناك طرق جديدة يبحث عنها العلماء لمساعدتنا للحصول على علاجات وأدوية أفضل. ربما في يوم من الأيام نجد علاجًا فعالاً لعلاج السرطان وتحسين حياة الذين يعانون من هذا المرض.

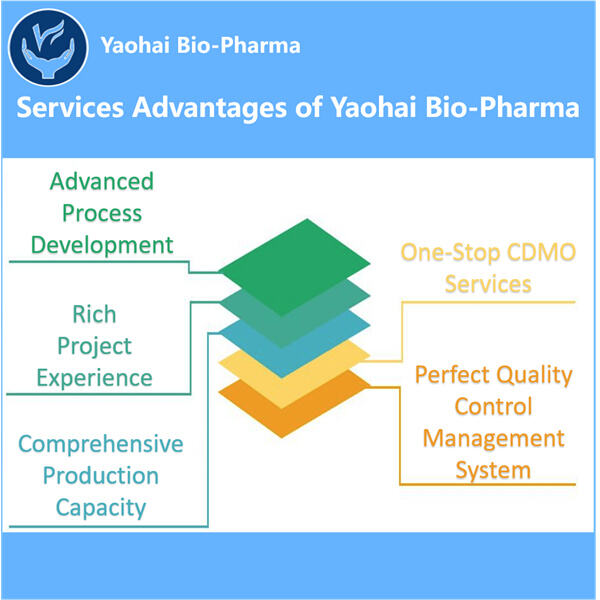

لدى ياوهاي بيو-فارما خبرة في تصنيع الأدوية البيولوجية المصنوعة من المجهريات. نقدم حلولًا مخصصة للأبحاث والتطوير وكذلك خدمات التصنيع مع تقليل المخاطر إلى الحد الأدنى. عملنا مع أنماط متنوعة مثل اللقاحات الفرعية рекомбинانت، الببتيدات، الهرمونات، السيتوكينات، عوامل النمو، الأجسام المضادة أحادية المجال، الإنزيمات، الحمض النووي البلازميدي، الرنا المرسال وغيرها. تخصصنا في عدة مجهريات مثلخميرة الإفراز الخلوي الخارجي والداخلي (مع إنتاج يصل إلى 15 جم/لتر)، البكتيريا القابلة للذوبان داخل الخلايا والأجسام الشاملة (مع إنتاج يصل إلى 10 جم/لتر). كما قمنا بإنشاء نظام تخمير BSL-2 لإنتاج VHH مضاد لـ HER3 وتصنيع اللقاحات. نحن خبراء في تحسين عمليات الإنتاج، زيادة الإنتاجية وتقليل التكاليف. لدينا فريق تقني كفؤ للغاية يضمن تسليم المشاريع في الوقت المحدد وبجودة عالية. وهذا يمكّننا من تقديم منتجاتكم الفريدة إلى السوق بشكل أسرع.

ياوهاي بيو-فارما، وهي واحدة من أكبر 10 مصنّعي المنتجات البيولوجية، متخصصة في التخمير المجهرى. لقد أنشأنا مصنعًا فعالًا يحتوى على مرافق متقدمة وقدرات قوية في البحث والتطوير والإنتاج. هناك خمس خطوط إنتاج مواد دوائية تتوافق مع معايير GMP للتخمير والت정ية الميكروبية، بالإضافة إلى خطين لتعبئة الأمبولات والكارتريدجز والإبر الجاهزة. تتراوح أحجام عمليات التخمير بين 100 لتر وإنتاج VHH مضاد لـ HER3 وفق معايير GMP. مواصفات التعبئة للأمبولات هي من 1 مل إلى 25 مل. أما بالنسبة للتعبئة في الكارتريدجز أو الإبر الجاهزة فهي من 1-3 مل. ورشة العمل الخاصة بالإنتاج متوافقة مع معايير cGMP وتضمن توفير العينات السريرية والتجارية بشكل مستمر. منشأتنا تنتج جزيئات كبيرة يتم شحنها حول العالم.

ياوهاي بيوفارما، واحدة من أكبر 10 شركات CDMO المجهرية، تدمج الأمور المتعلقة بالجودة والتنظيم. لدينا نظام جودة متوافق تمامًا مع المعايير الحالية لـ GMP وكذلك اللوائح الدولية. فريق خبراء التنظيم لدينا لديه فهم عميق للإطارات التنظيمية العالمية. هذا يمكّننا من تسريع إطلاق المنتجات البيولوجية. نحن قادرون على ضمان إجراءات إنتاج قابلة للتتبع ومنتجات ذات جودة عالية تتماشى مع اللوائح الصادرة عن إدارة الغذاء والدواء الأمريكية (FDA)، وإنتاج VHH مضاد لـ HER3 وفق معايير GMP، وهيئة الصحة الأسترالية (TGA)، وإدارة الأدوية الوطنية الصينية (NMPA). لقد نجحت ياوهاي بيوفارما في اجتياز التدقيق الميداني الذي أجرته شخصية مؤهلة (QP) من الاتحاد الأوروبي لنظام الجودة الخاص بنا وموقع الإنتاج. كما مررنا أيضًا بمراحل التدقيق الأولية لنظام إدارة الجودة ISO9001 ونظام إدارة البيئة ISO14001.

ياوهاي بيو-فارما، وهي شركة رائدة في مجال خدمات CDMO الخاصة بالمنتجات الحيوية الدقيقة، مقرها في جيانغسو. كنا نركز على العلاجات واللقاحات المنتجة بواسطة الكائنات الدقيقة والتي تتناسب مع الاستخدام البشري، البيطري وإدارة إنتاج GMP Anti-HER3 VHH. لدينا أكثر التقنيات المتقدمة لتطوير الأبحاث وتصنيع منتجات تغطي العملية بأكملها من هندسة سلالات دقيقة، بنوك الخلايا وكذلك تطوير العمليات والطرق إلى التصنيع السريري والتجاري، مما يضمن توفير الحلول الأكثر تطوراً بنجاح. قدمنا خبرة كبيرة في معالجة الكائنات الدقيقة الحيوية. أنجزنا أكثر من 200 مشروع حول العالم وساعدنا عملائنا في فهم القوانين واللوائح الخاصة بـ FDA الأمريكي، EMA الأوروبي، TGA الأسترالي و NMPA الصيني. المعرفة المتخصصة والخبرة الواسعة تمكننا من التكيف بسرعة مع احتياجات السوق وتقديم خدمات CDMO مخصصة.