Anpassung, Effizienz & Kosteneffektivität

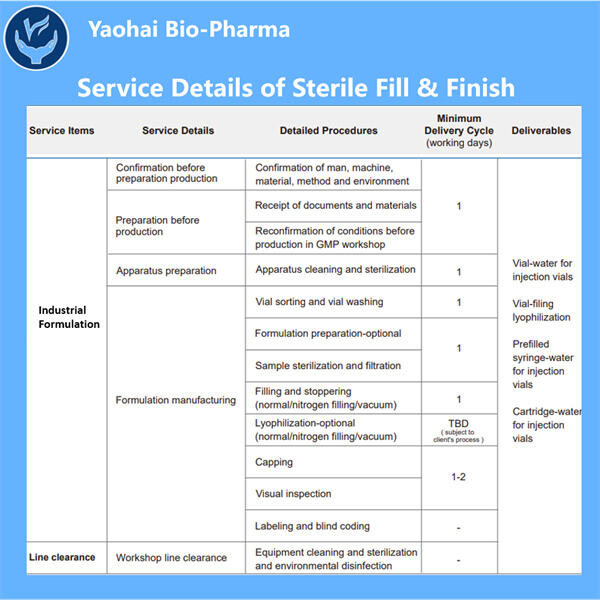

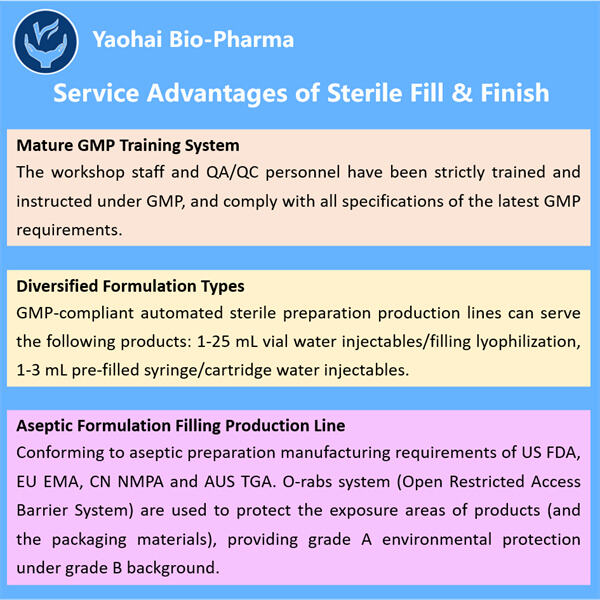

Yaohai Bio-Pharma hat Erfahrung in der Herstellung von Biologika, die aus Mikroorganismen erstellt wurden. Wir bieten maßgeschneiderte RD-Lösungen sowie Fertigungsdienstleistungen an und minimieren dabei das Risiko. Wir haben mit verschiedenen Modalitäten gearbeitet, wie rekombinanten Subeinheitsimpfstoffen, Peptiden, Hormonen, Cytokinen, Wachstumsfaktoren, Mono-Domän-Antikörpern, Enzymen, Plasmid-DNA, mRNA und anderen. Wir haben uns auf mehrere Mikroorganismen spezialisiert, wie Hefextrazellulär und intrazellulärer Sekretion (Ausbeute bis zu 15g/L), Bakterien intrazellulär löslich und Inklusionskörper (Ausbeute bis zu 10g/L). Wir haben außerdem ein BSL-2-Fermentiersystem entwickelt, um Sterilfüllung und -abschluss von Impfstoffen durchzuführen. Wir sind Experten darin, Produktionsprozesse zu optimieren, Ausbeuten zu erhöhen und Kosten zu senken. Wir verfügen über ein hoch effizientes Technologie-Team, das rechtzeitige und qualitativ hochwertige Projektrealisierungen sicherstellt. Dadurch können wir Ihre einzigartigen Produkte schneller auf den Markt bringen.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN