Professionelles Know-how & umfangreiche Erfahrung

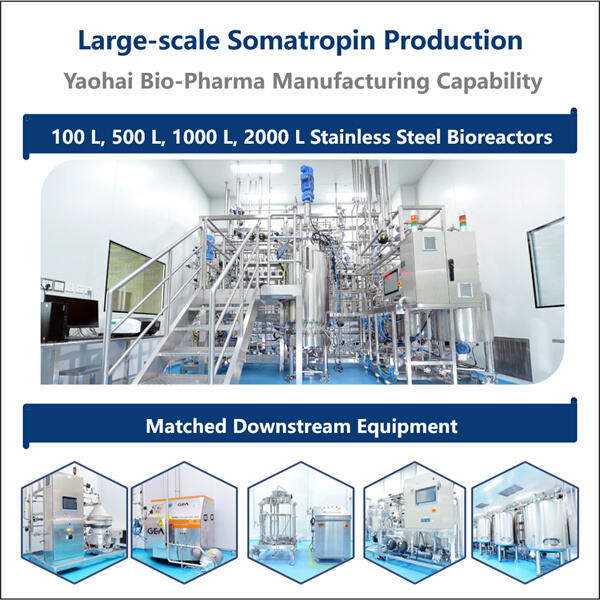

Yaohai Bio-Pharma, ein führender Anbieter von CDMOs für mikrobielle Biologika, hat seinen Hauptsitz in Jiangsu. Wir konzentrieren uns auf mikrobiell hergestellte Therapeutika und Impfstoffe, die für den Einsatz bei Menschen, in der Veterinärmedizin und zur GMP-Somatotropinproduktion geeignet sind. Wir verfügen über die fortschrittlichsten Forschungs- und Produktionstechnologieplattformen, die den gesamten Prozess abdecken – von der Mikrobenstamm-Ingenieurtechnik, Zellenbanking sowie Verfahrensentwicklung bis hin zur kommerziellen und klinischen Fertigung, um einen erfolgreichen Versorgungsprozess mit den modernsten Lösungen sicherzustellen. Wir haben eine große Menge an Erfahrung in der biologischen Verarbeitung mikrobieller Zellen gesammelt. Wir haben weltweit über 200 Projekte abgeschlossen und unsere Kunden bei der Bewältigung der Vorschriften der US-FDA, EU-EMA, Australien-TGA und China-NMPA unterstützt. Unser Fachwissen und unsere umfangreiche Erfahrung ermöglichen es uns, flexibel auf Marktbedürfnisse einzugehen und maßgeschneiderte CDMO-Dienstleistungen anzubieten.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN