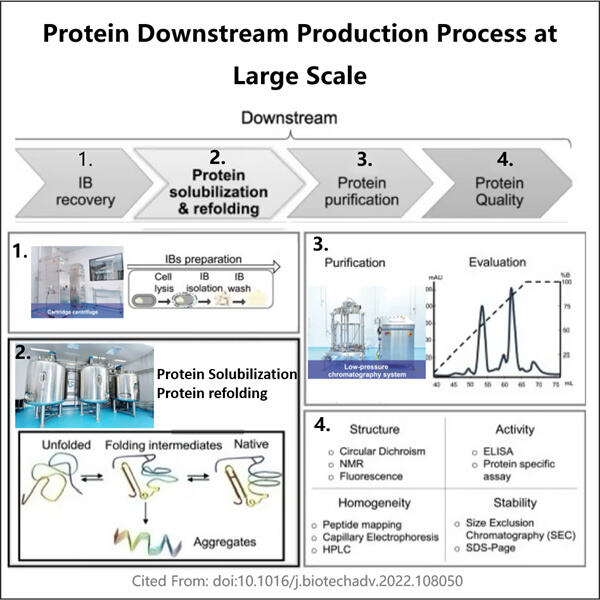

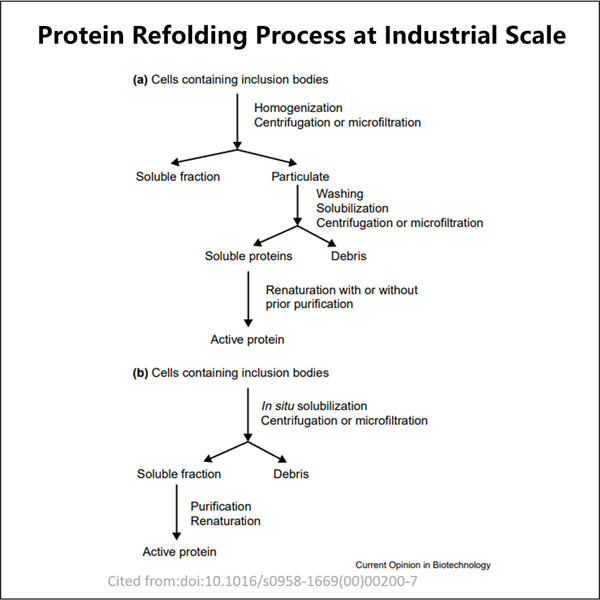

Eiweiß spielt eine entscheidende Rolle in dem, was unser Körper tut. Dies hilft uns wiederum zu wachsen, stark zu sein und gesund zu bleiben. Eiweiß baut unsere Muskeln und Organe auf. Verdauungsenzyme helfen uns auch, Krankheiten zu bekämpfen und lebenswichtige Nährstoffe zu transportieren, die unser Körper benötigt. Eiweiße können sich verfilzen und so ihre richtige Faltung verlieren. Wenn dies passiert, entstehen Chaos in unserem Körper, das zu Zuständen wie Alzheimer und Krebs etc. führen kann. Was jedoch wirklich die gefalteten Prionen charakterisiert, ist, dass sie ungewöhnliche Größen und Formen annehmen, was bedeutet, dass diese winzigen gebrochenen Stücke weit entfernt sind von einem Zusammenschluss, bis man sie mit bloßem Auge sehen kann, sobald es soweit ist — ein sehr spezifischer Proteinrefalungsprozess. Wenn wir dies skalieren wollen, könnte es in einigen Fällen eine Herausforderung und schwierig sein, aber die Verbesserung unserer Gesundheit ist absolut essenziell. Aber warum müssen wir Eiweiße überhaupt "refalten", wie wird dies tatsächlich von den Wissenschaftlern durchgeführt, die daran arbeiten, und welche Hindernisse stoßen sie unterwegs auf sowie ihre potenziellen Anwendungen in Vorgeführtes Insulin medizin und Technologie

Proteinrefolding ist von entscheidender Bedeutung bei der Entwicklung neuer Medikamente, die zur Heilung verschiedener Krankheiten verwendet werden. Es gibt viele Krankheiten, von Alzheimer bis hin zur Mukoviszidose, die auftreten, wenn Proteine verfilzen und versagen. Wenn wir uns die Pharmaindustrie ansehen, benötigen diese Unternehmen eine große Menge ordnungsgemäß gefalteter Proteine, um neue Medikamente herzustellen. Früher war das Gewinnen der Proteine so einfach wie ihre Extraktion aus ihrer natürlichen Quelle, aber diese alte Methode ist nicht in der Lage, uns genug derartiger Proteine zu liefern, die unsere moderne Welt erfordert. Aus diesem Grund müssen Wissenschaftler nach verbesserten und kostengünstigen Methoden suchen, um ordnungsgemäß gefaltete Proteine zu erhalten. Hier können Wissenschaftler auf großes Proteinrefolding zurückgreifen, das es ihnen ermöglicht, die für Medikamente notwendigen Proteine in größerem Maßstab herzustellen.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN