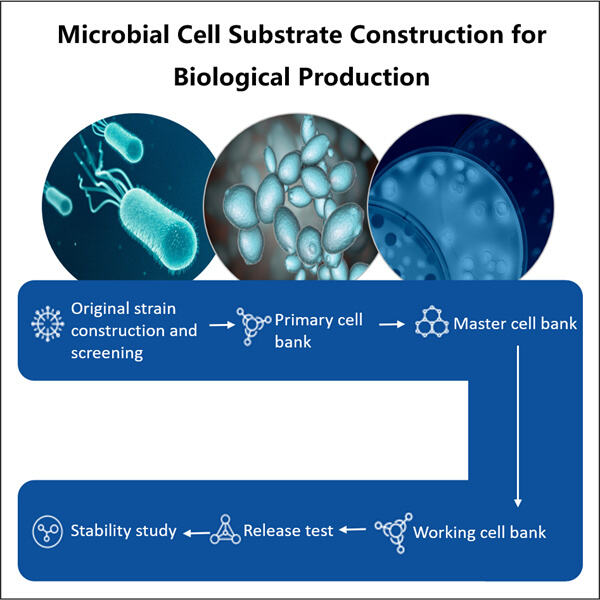

Apakah Anda pernah berhenti untuk berpikir bagaimana hal-hal seperti obat-obatan atau makanan dibuat? Anda mungkin terkejut mengetahui bahwa mereka adalah makhluk tak terlihat yang dikenal sebagai sel mikroba. Yaohai ini Peningkatan Skala Proses Biopharmaseutika Mikroba lebih kecil dari yang hanya bisa dilihat di bawah mikroskop. Bulan lalu, saya belajar bahwa Yaohai mengetahui banyak tentang penggunaan sel mikroba untuk pengembangan produk. Nah, mari kita lihat lebih dalam apa yang mereka lakukan dan mengapa.

Ada kehidupan mikro yang sangat kecil, dikenal sebagai sel mikroba di mana-mana. Mereka ada di udara, mereka ada di air. Mereka juga banyak ditemukan di kulit kita. Meskipun kita tidak bisa melihatnya, ada banyak ide yang muncul dari hal ini. Sel mikroskopis ini dapat menghasilkan berbagai jenis molekul, mulai dari obat-obatan, bahan makanan hingga material-material yang berguna. Kemampuan untuk memproduksi barang-barang menggunakan sel mikroba disebut "bio-proses" atau "bio-manufaktur." Bukankah luar biasa bagaimana hal-hal kecil bisa menghasilkan penemuan dan produk besar?

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

UR

UR

BN

BN